RECOMMENDATION FOR USE, CARE INSTRUCTIONS, AND USER INFORMATION

QUALITY PRODUCT – YOU HAVE CHOSEN WELL

With this Rukapol® shoe, you have acquired a real quality product characterised by special technical features, functionality, and – above all – a perfect fit. Selected materials and the best workmanship guarantee long life and optimum wearing comfort.

We wish health, safety, and accident-free wearing with our shoes.

Your Rukapol® – team

RECOMMENDATIONS FOR USE AND CARE

This product is characterised by a perfect fit. The determination of the shoe size and width is therefore even more important! To determine your size, please use only our analogue or digital Rukapol® measuring system.

From a foot ergonomic point of view, the production of five different widths per shoe size represents an optimum fit and the associated foot health!

The locking systems must be used properly. The shoe laces must be well tightened.

The shoes must be cleaned and maintained with suitable care products and special tools. Recommended: Toko care products!!

Do not dry shoes near heaters. It is recommended to dry the shoes at room temperature and/or in airy rooms.

In the course of regular maintenance, the following should be checked for externally visible damage: tread of the outsole, functionality of the closure, whether steel toe cap is visible. Attention: This damage reduces the protective function of the shoe!

In order to determine the type of shoes to be used, the possible hazards must be identified according to the workplace evaluation, and a precise needs analysis must be carried out by a specialist consultant. A longer service life of the shoe is thus achieved, and wearer satisfaction increases.

For the ideal shoe climate, we recommend a functional sock made of merino wool and polyamide. It should have at least 50% merino wool content.

The shoes must be stored properly, as packaged.

WARRANTY

The warranty period for our products is 12 months from delivery of the goods for material and processing defects. Excluded from this warranty are parts that are subject to natural wear and tear (e.g. outsoles). Also excluded are damages that occur to the product within the scope of its protective function. We also cannot accept responsibility for damage caused by improper care and incorrect use. However, such damage can be repaired by us at cost price provided that this is technically possible.

Because of the ageing process of the materials, especially of the outsole and the sole adhesives used, it is no longer recommended to wear the shoes after 5 years from the production date (visible on the label on the inside of the shoe tongue).

USER INFORMATION FOR EN ISO 20345:2011

This pair of safety shoes complies with EN ISO 20345:2011 in conjunction with EN ISO 20344:2011.

The CE mark means that our shoes have been tested and certified by the accredited test institute PFI, D-66930 Pirmasens. The basic and additional requirements that determine the degree of protection of the shoe are to be taken from the marking on the shoe. These include:

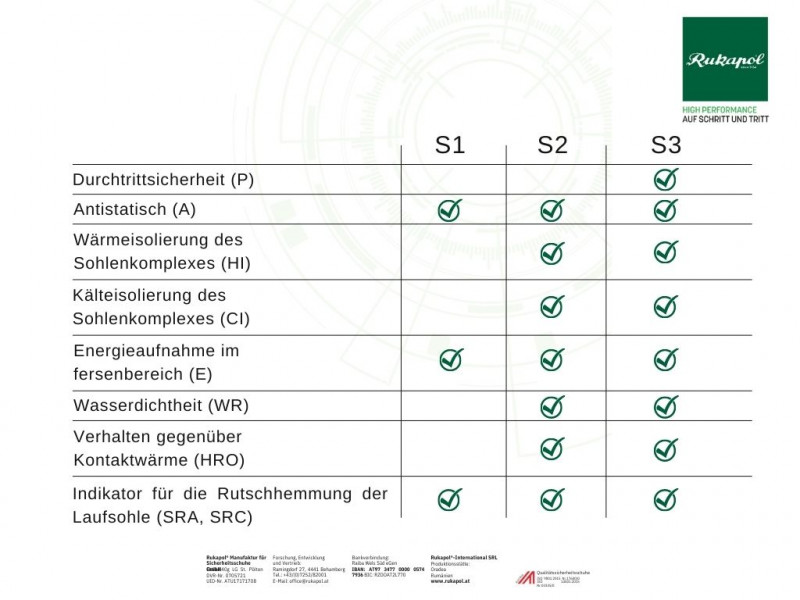

PROPERTIES OF THE SYMBOLS FOR THE ADDITIONAL REQUIREMENTS:

- P Resistance to penetration

- HI Thermal insulation

- CI Cold insulation

- HRO resistance of the outsole to contact heat

- WR Waterproofing of the entire shoe

- SRA Slip resistance indicator

- SRC Slip resistance indicator

NOTE

Because all materials, including the first-class materials we use, are dependent on time, a storage period of more than 2 years is not recommended. In the case of unsuitable storage conditions, the service life of the shoes is considerably reduced.

The main influencing factors are:

- Temperature

- Humidity

- Change in material properties

The expiration time depends on the degree of wear and tear, the use, and the area of application.

OUTSOLE

The quality information on the outsole “oil, petrol, and acid resistant” refers only to the outsole and not to the upper. The sole is fuel resistant according to EN ISO 20344:2011; it is conditionally oil and acid resistant. In general, all soles are not resistant to strong chemicals (e.g. acids, bases). The heat resistance of PU soles is about 90°C; that of rubber soles about 180°C. The slip resistance of the outsole is always strongly dependent on the floor covering, which can also be influenced by intermediate media.

REMOVABLE INSOLES

The shoes are equipped with a removable insole. We would like to point out that the tests were carried out with this removable insole. The shoes may therefore only be used with this removable insole. The removable insole may be replaced only by an insole of comparable quality to the original insole.

ANTISTATIC SHOES

Antistatic shoes should be used when there is a need to reduce electrostatic charge by dissipating the electrostatic charges so that the risk of ignition of flammable substances and vapours by sparks is eliminated as well as when the risk of electric shock from an electrical device or live parts is not completely eliminated. However, it should be noted that antistatic shoes cannot provide sufficient protection against electric shock as it only builds up resistance between the ground and the foot. If the risk of electric shock cannot be completely eliminated, further measures must be taken to avoid this risk. Such measures and the tests specified below should be part of the routine workplace accident prevention programme. Experience has shown that for antistatic purposes, the path through a product should have an electrical resistance of less than 1000 MΩ throughout its lifetime. A value of 100 kΩ is specified as the lowest limit for the resistance of a new product to provide limited protection against dangerous electric shock or ignition because of a defect in an electrical device when working at up to 250 V. However, it should be noted that under certain conditions, the shoe does not provide sufficient protection; the user of the shoe should therefore always take additional protective measures. The electrical resistance of this type of shoe can change considerably as a result of bending, dirt, or moisture. This shoe will not perform its intended function when worn in wet conditions. It is therefore necessary to ensure that the product is capable of performing its predetermined function of discharging electrical charges and providing protection during its service life. The user is therefore recommended to regularly carry out an on-site inspection of the electrical resistance if necessary.

Shoes of classification I can absorb moisture when worn for a longer period of time and become conductive in wet and humid conditions. If the shoe is worn in conditions in which the sole material is contaminated, the user should check the electrical properties of the shoe each time before entering a hazardous area. In areas where antistatic shoes are worn, the ground resistance should be such that the protective function provided by the shoe is not cancelled out.

During use, no insulating components should be placed between the inner sole of the shoe and the user’s foot. If an insole is inserted between the inner sole of the shoe and the user’s foot, the electrical properties of the shoe/insole connection should be checked.

PUNCTURE RESISTANCE – NOTE

The shoes are equipped with a non-metallic anti-puncture insole.

The penetration resistance of these shoes was measured in the laboratory using a nail with a conical tip.

The diameter of the nail tip is 4.5 mm and is measured with a force of 1100 N. Higher forces or nails with smaller diameters increase the risk of penetration. In such conditions, alternative preventive measures should be considered.

All user information and protection categories can be found in the document below:

Download: Recommendation for use, care instructions, and user information